Forming Line manufactures straightener servo feeders with varying feeding capacities.

Machinery, Production Lines and Products related with forming of the sheet material.

T: +902623432290

Email: [email protected]

FORMING LINE

Sahil Mah. Liman Cad. No: 132 Basiskele 41090 KOCAELI / TURKEY

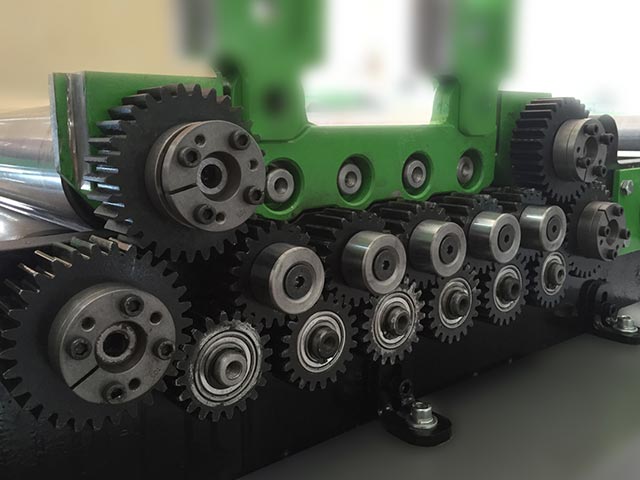

USE OF PNEUMATIC PISTONS

Straightener with Servo Feeders have roller pressure adjustment with pneumatic pistons. Feeder and straightener rollers are driven and adjusted together by a gear group.

PURPOSE OF STRAIGHTENER WITH SERVO FEEDER

Straightener with Servo Feeder's design purpose is to relieve sheet metal tension hence enabling a proper piloting to work ideally with a multipurpose progressive mold system.

Combination systems of Servo Feeder and Straightener, we call is RMS Models, are designed to feed high performance presses automatically since straightener and feeder roller groups are combined in single machine.

Straightener with Servo Feeder enables customers to save space thanks to the integrated design. This eliminates the material loop between Straightener and Servo Feeder. Decoiler and Straightener with Servo Feeder are combined to work together.

USAGE

Straightener with Servo Feeders are easy to set up, run, control and install.

Servo Motor power transmission used in the machinery is designed with full surface contact of gears and minimum loss in the transfer of the power. The same power transmission system gives power to the feeder and straightener rollers.

Straightener with Servo Feeder feeds sheet metal in parallel with mold surface. Feeder width adjustment is centralized and able to shift 50 mm to the left and to the right.

Straightener with Servo Feeder is able to feed sheet metal in a pre-programmed speed, with high precision and with an automatic cycle method.

FEEDING SPEED

General feeding speed of the machine is 44 meters per minute (44 m/min.)